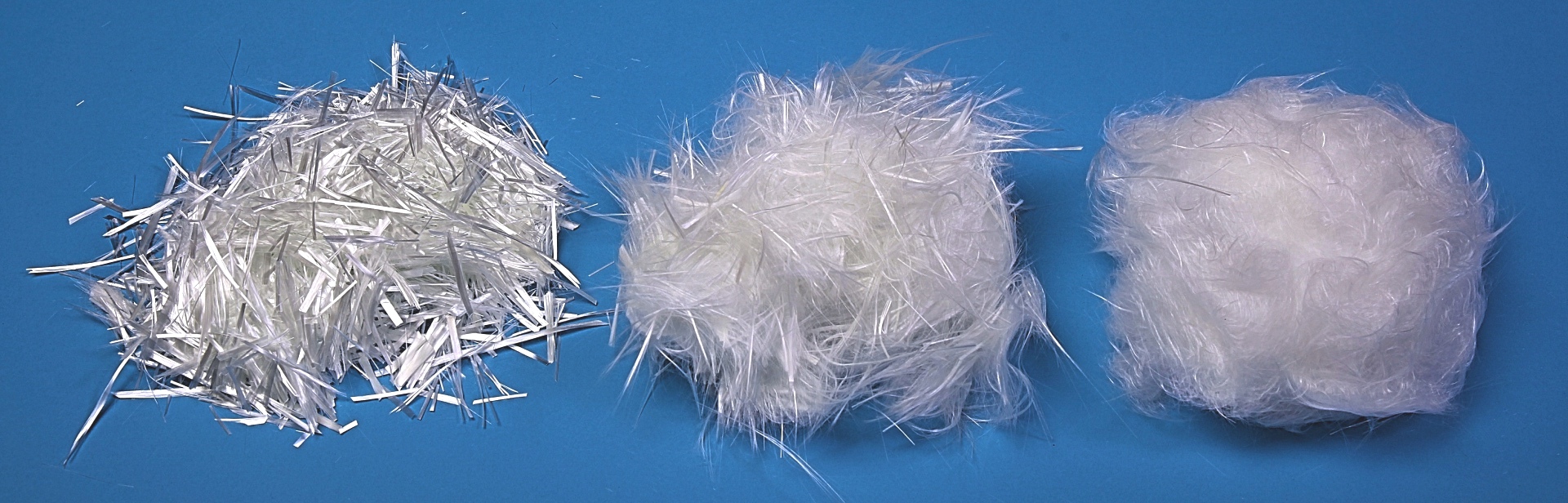

Glass Fibre

- Glassman Fibres are designed to use in dry mix systems or other premixing processes. The glass strands reinforcement at low permits efficient dosages. It has the flowing properties-Good liquidity and integrity. Glassman glass Fibres are also used at low addition level to prevent cracking & improves the performance in concrete. Glassman glass fibres do not protrude through the surface and require no additional finishing procedures. Adding glass fibres in concrete minimizes early shrinkage cracks during the concrete setting phase. lt works best for shrinkage cracks and with Steel Fibre mix for reinforcement and flooring. It is extensively used for spray concrete, plastering in buildings and structural works like beams and columns. There are two types of glass fibres- AR glass fibres which is Alkaline resistant and E-glass fibres which has low alkaline resistance.

Advantage of Laser Guided Screed Flooring

- Easy mixing

- No Rusting

- Increases durability

- Crack control

- Suitable for both premix and spray.

- Chemical Resistance and high Modulus of elasticity.

- Used in Precast products for anti-crack benefits.

- It is particularly suited to the preparation of pre-bagged mixes of special mortars or renders.

Applications

- Flooring with steel fibres to avoid surface cracks.

- Plastering Concrete products (Precast pipes, paver blocks and bricks.

- Readymix concrete.

- Dry mix.

- Exterior panels.

Our Elite Clients

We Serve Clients Nationwide